Profile:

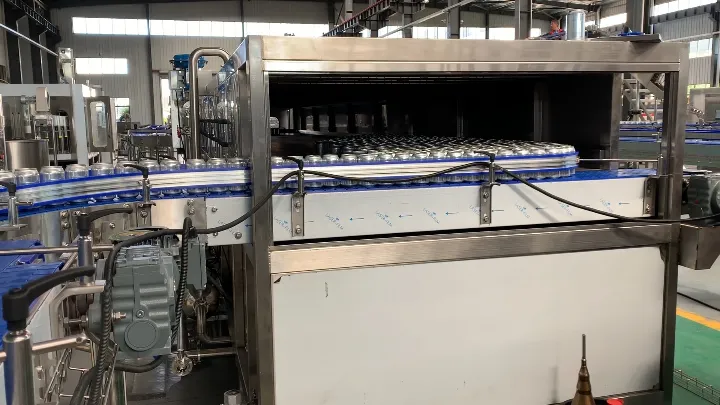

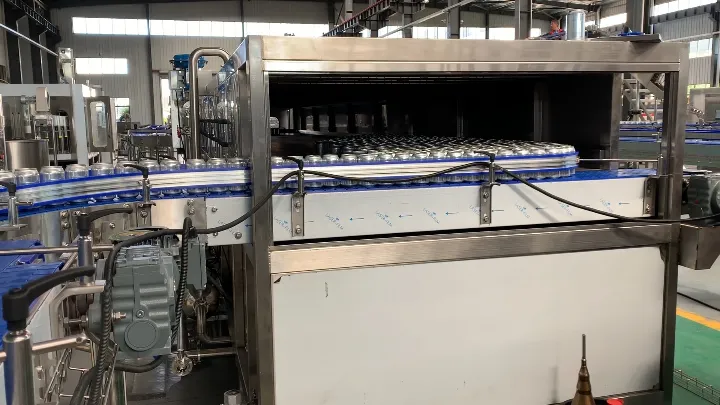

WP type spraying cooling machine are developed on base of absorbing advanced technique from home and abroad. With three zones treatment of circulated cooling water and the treatment time can be adjusted according to the user's requirement. The machine can applicable to all types non-carbonated material such as tea, juice, sauce. The machine body is made of SUS304 stainless steel and can run stably and smoothly.

Feature:

1. High reliability conveying device and flexibility speeding system

The conveying belt for bottles is high strength plastic chain net which has god strength and abrasion proof.The driving conveying adopts stepless motor which can change the speed of conveying belt easily.

2. high effective spraying system

Via arranging the atomization nozzles on the chain plate in order to spray the bottles evenly, the spraying water can be utilized completely and the spraying covers large area

3.The temperature can be controlled flexibly and easily set

The machine adopts temperature controlling system which can control the temperature exactly and be sensitive to the response. Press the button to set temperature between 0-100ºC

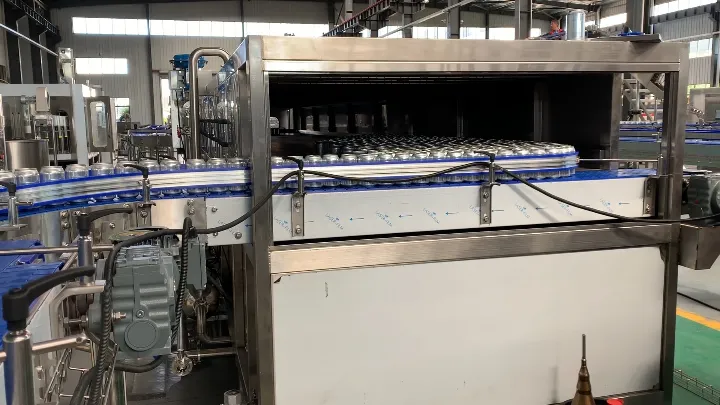

Main technical parameters:

1. capacity :250ml PET bottle :8000 Bottles/h

2. set temperature and cooling treatment time :total treatment time :35minutes

3. applicable bottle size : diameter 50-110, height :H300mm

4. effective treatment area:10.54m2

5. electricity power consumption :13.25kw

among this : main motor 0.75kw

6. water cooling consumption

1.water starting consumption : 15t

2.water running consumption : 30-42kg/H

3.the cooling capacity of the cooling column: 60m3/h,(the cooling column should be supplied by the user).

7. Overall size

LWH=1000010001670

WORKIGN HEIGHT :H=1250mm

8.weight: 3.6t