Views: 0 Author: Site Editor Publish Time: 2025-03-03 Origin: Site

The cold filling process is a revolutionary method in the beverage and food manufacturing industry, specifically designed to ensure the safe, efficient, and high-quality packaging of liquids like juices, beer, and other beverages. Unlike traditional hot filling, this method uses lower temperatures to preserve the taste, texture, and nutritional value of beverages, while also maintaining their safety for consumption. It’s particularly popular with sensitive beverages that require precise handling, such as juices, carbonated drinks, and beer.

For manufacturers aiming to stay competitive in today’s market, understanding the cold filling process and its connection to advanced conveyor equipment and machinery is vital. In this article, we’ll break down the essentials of the cold filling process, explore its applications, and highlight how cold aseptic filling systems play a critical role in modern beverage production.

The cold filling process involves filling beverages or liquids at low temperatures, typically between 0°C and 4°C (32°F and 39°F), to ensure the product remains fresh and uncontaminated. This process is especially crucial for sensitive liquids like juices and carbonated drinks, which can lose their flavor or quality when exposed to high temperatures.

Sterilization: The product and the packaging (bottles, cans, etc.) are sterilized to remove any harmful bacteria or microorganisms.

Cooling: The beverage is cooled to near-freezing temperatures before being filled into containers.

Filling: Using advanced machinery like a cold aseptic filling machine, the liquid is filled into sterilized bottles or cans in a controlled environment.

Sealing: Once filled, the containers are sealed immediately to maintain freshness and prevent contamination.

This method is highly effective when used with conveyor equipment, which ensures the smooth transfer of bottles or cans through each stage of the process.

Why has the cold filling process become such a game-changer? Here are some of the key benefits that make it stand out in the beverage packaging industry:

Unlike traditional hot filling, which can compromise the taste and quality of beverages, the cold filling process preserves the natural flavor and nutrients of products. This is especially important for juices and carbonated drinks.

By filling beverages in a sterile and temperature-controlled environment, the cold aseptic filling process ensures a longer shelf life without the need for preservatives. This is a win-win for manufacturers and consumers alike.

The cold filling process is more energy-efficient than hot filling methods, as it eliminates the need for heating large quantities of liquid. This makes it an environmentally friendly option for manufacturers.

From juices to beer and even soft drinks, the cold filling process can handle a wide range of beverages. It’s compatible with various machinery, including juice filling machines, beer filling machines, and can filling machines.

A key component of the cold filling process is the cold aseptic filling machine. This advanced equipment ensures that beverages are filled in a sterile environment, minimizing the risk of contamination.

A cold aseptic filling machine is designed to fill sterilized containers with sterilized beverages in a contamination-free environment. This machine is ideal for products like juices, which require a high level of hygiene.

A cold aseptic filling line typically includes:

Sterilization units for cleaning containers and caps.

Precise conveyor equipment for transporting bottles or cans.

Filling valves designed to handle liquids at low temperatures.

Sealing mechanisms to ensure airtight closure.

Compared to traditional filling systems, a cold aseptic filling system eliminates the need for preservatives while still ensuring a long shelf life. This system is particularly critical for sensitive beverages like beer, where maintaining taste and carbonation is essential.

The cold filling process is versatile and widely used across various industries. Here are some of the most common applications:

Juice Filling: The process is ideal for juices, as it preserves their natural flavor, color, and nutrients. A reliable juice filling machine is essential for this application to ensure the quality of the final product.

Example: YeTai Cold-Pressed Coconut Juice with Pulp: This coconut juice uses aseptic cold-fill technology to lock in the natural flavor of fresh coconut pulp. Each sip delivers delicate pulp particles and a multi-layered texture, offering a rich, sweet taste without cloying sweetness.

Canned Beverages: The cold filling process is also used for canned beverages, including soft drinks and carbonated water. A can filling machine is designed to handle these products with precision, ensuring consistent quality.

Innovative Tea and Fruit Blends:

Sugar-Free Jasmine Oolong Tea: Brands like Suntory Sugar-Free Jasmine Oolong Tea utilize aseptic cold-fill technology to preserve the authentic aroma of tea leaves and jasmine flowers. With zero added sugar and a crisp, refreshing taste, it caters to health-conscious consumers.

Sugar-Free Lemon Jasmine Tea: Made from high-mountain tea leaves and freshly squeezed lemon juice, this beverage is produced using aseptic cold-fill processes without preservatives. Its tangy, floral notes make it an ideal pairing for spicy or greasy meals.

Beer Filling: For breweries, maintaining the taste and carbonation of beer is a top priority. The cold filling process, along with a specialized beer filling machine, ensures that the beer retains its freshness from production to consumption.

No cold filling process would be complete without high-quality conveyor equipment. This essential machinery ensures the seamless movement of bottles or cans through each stage of the process, from sterilization to sealing.

Efficiency: Conveyor systems reduce bottlenecks, ensuring a steady flow of products. This is especially critical for high-output production lines.

Precision: Advanced conveyor systems are designed to handle delicate products, such as glass bottles or thin aluminum cans, without causing damage.

Versatility: Conveyor equipment can be customized to work with various machines, including juice filling machines, beer filling machines, and can filling machines.

Q1:What is the difference between the cold filling process and hot filling?

A1:The main difference lies in temperature. The cold filling process uses lower temperatures to preserve the natural flavor and nutrients of beverages, whereas hot filling involves heating liquids to kill bacteria, which can sometimes alter the taste and quality.

Q2:What types of beverages can be processed using the cold filling process?

A2:The cold filling process is ideal for sensitive beverages like juices, beer, carbonated drinks, and soft drinks. It’s also suitable for products that require a long shelf life without preservatives.

Q3:Do I need specific machinery for the cold filling process?

A3:Yes, specialized machinery like a cold aseptic filling machine is required. Additionally, conveyor equipment plays a crucial role in ensuring the smooth operation of the production line.

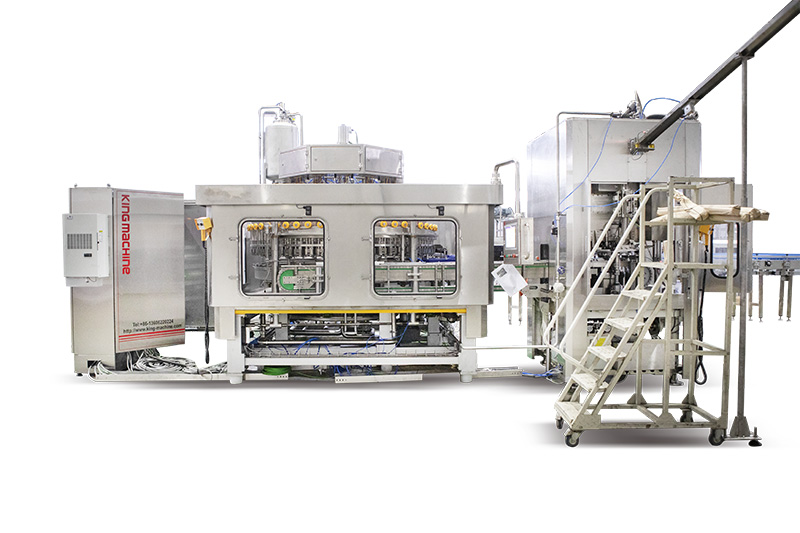

If you're looking to enhance your production line with cutting-edge technology, King Machine offers a wide selection of high-performance equipment tailored to your needs. Whether you need an advanced cold aseptic filling machine for juices, a high-efficiency beer filling machine to maintain taste and carbonation, or a precise can filling machine for carbonated beverages, we have the right solution for you.

Cold Aseptic Filling Machines: Ensure a sterile and contamination-free filling process for sensitive beverages.

Conveyor Equipment: Designed to optimize efficiency and product movement across your production line.

Beverage Filling Machines: High-quality solutions for water, beer, juice, and carbonated drinks.

No matter the scale of your production—whether you’re a small business or a large-scale manufacturer—King Machine provides the expertise and technology to help you succeed. Get in touch with us today to find the best filling and packaging solutions for your business!